-40%

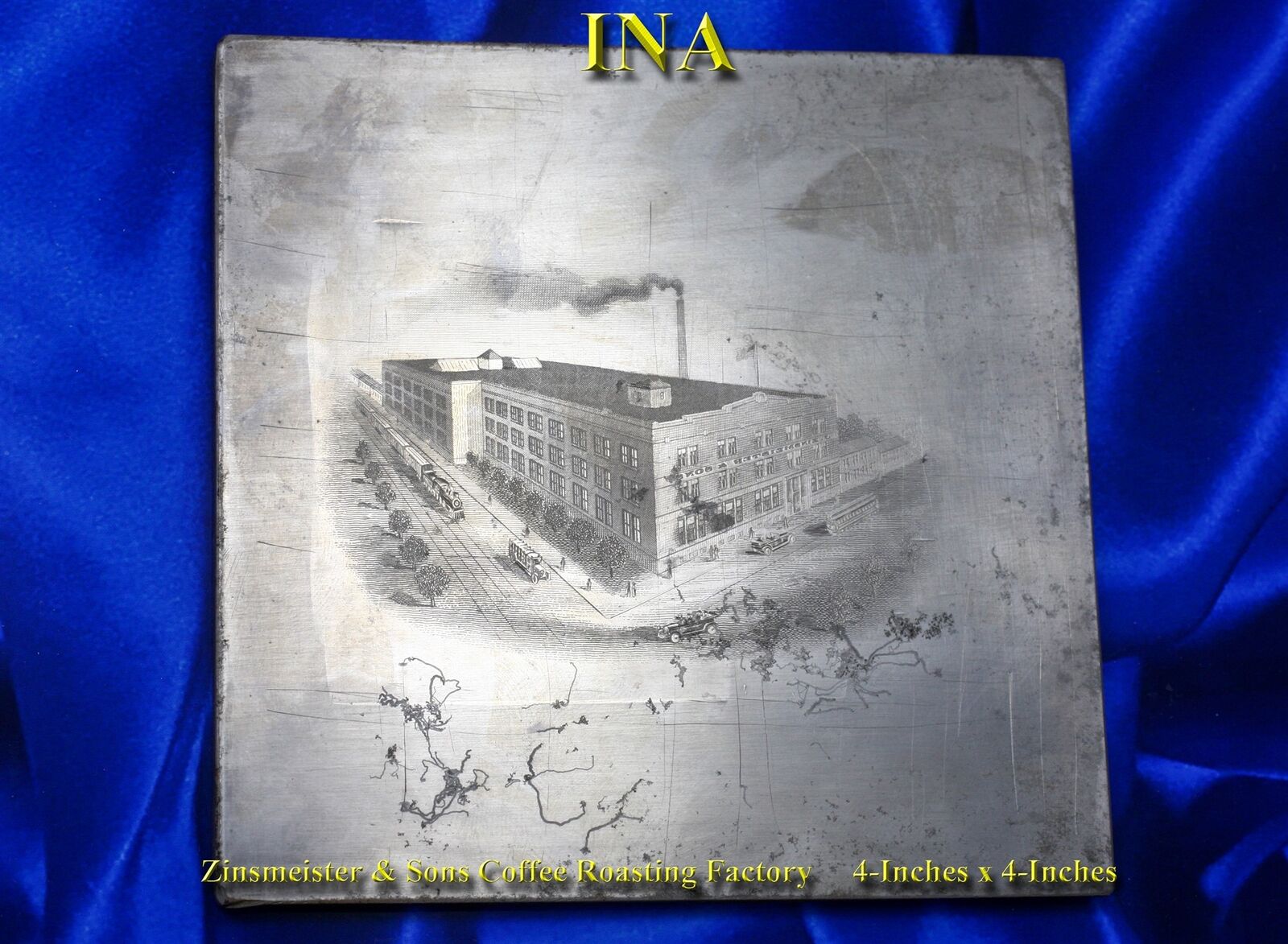

INA Steel Engraving Plate 4x4 J Zinsmeister & Sons coffee roasting factory Rare

$ 208.56

- Description

- Size Guide

Description

AuctionsBuy It Now

Ending Today

View Feedback

Store Newletter

Visit Store

Contact Me

Here is an original steel engraving plate. It depicts the Jacob Zinsmeister & Sons coffee roasting factory in Louisville, KY.

Jacob Zinsmeister, of J. Zinsmeister & Sons, was an old-time Louisville coffee man. Before he started roasting, he was a big factor in the green coffee trade. The business was established in 1866 at New Albany, Ind., by Frank Zinsmeister, Sr., but was later moved to Louisville, KY. Jacob Zinsmeister was taken into the business in 1872, and the name was changed to Frank Zinsmeister & Son and later on to J. Zinsmeister & Sons.

The plate comes with the original paper holder and a print attached to the holder.

Measurements: 4"x 4" and 3/16" thick.

This is just a magnificent example of the artistic skill of America engravers.

Item#: 9581

Issue: Vignettes

United States of America

Kentucky , Louiville

Very Nice Quality

Very Rare

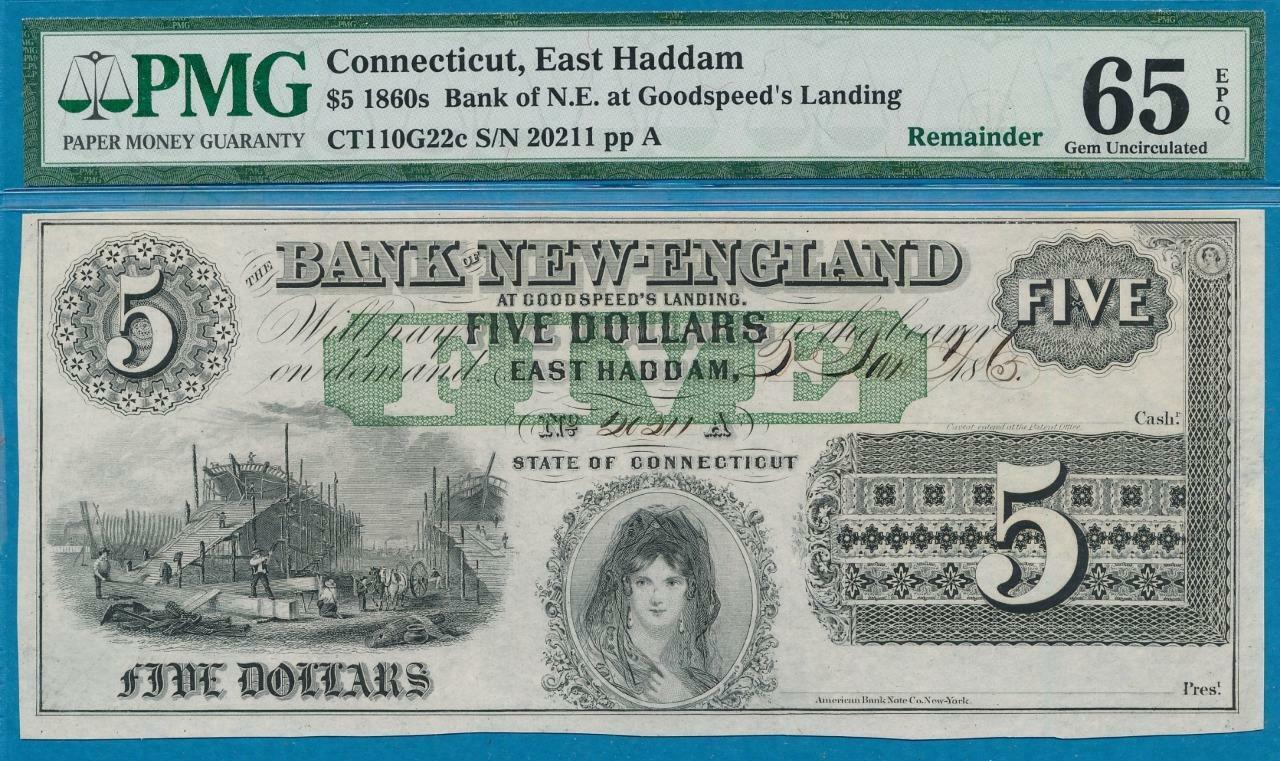

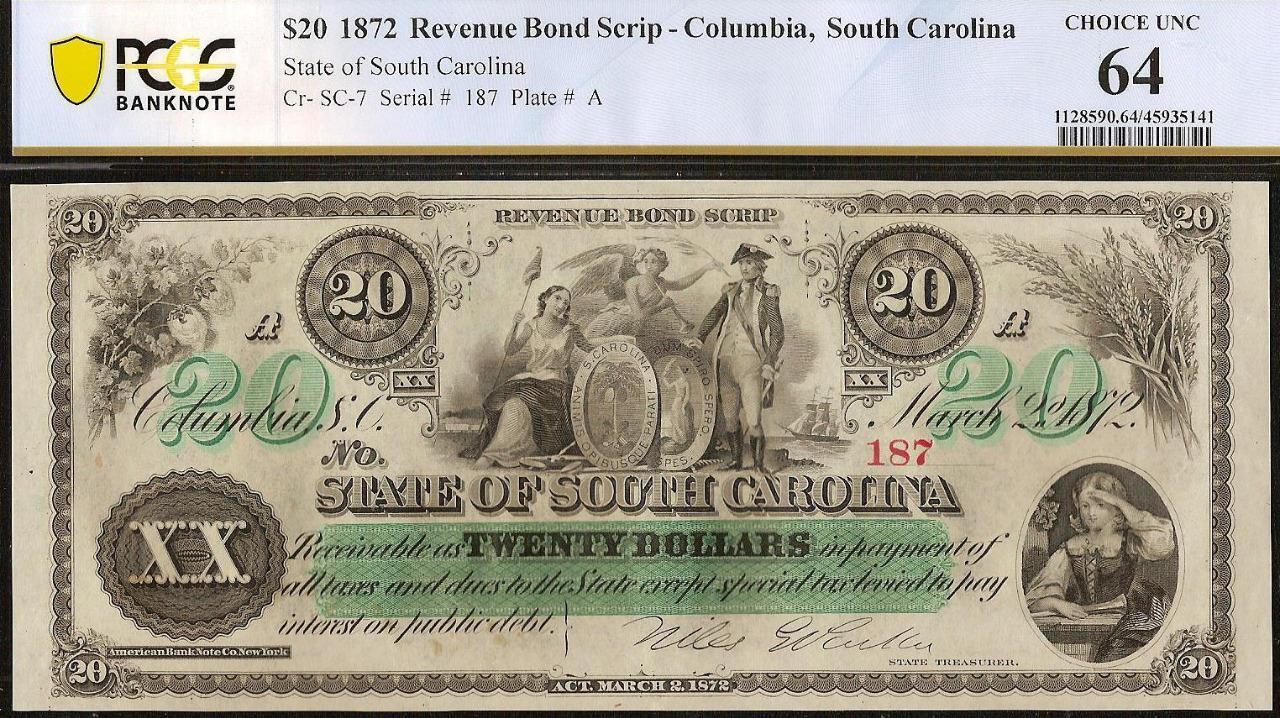

A note on quality of Obsolete Bank Notes.

Unlike regular US Government notes, bank notes were not printed on the finest of cotton-bond paper or with the best of inks. They were not meant to circulate for a long period of time or circulate throughout the nation. They usually circulated on a local or state level, and probably not more then a few years at best. They were printed on whatever paper was available at the time. On some notes one can see some of the wood or pulp chips in the paper. In some cases, they were printed on earlier notes that were no longer in use. The technology of acid-free paper was not there yet, as seen with some of our national historical documents, and paper was much scarcer than we can today imagine.

These notes had to be printed on semi-wet or moist paper, or the ink would not properly adhere. They were very labor intensive, and were printed by hand, one side at a time. They would manually ink the press, place the damp sheet in it, and run the roller over it. The sheet would be hung to dry, and the same process of wetting and printing would be repeated for the reverse. In the case where more than one color was used, the process would have to be repeated for each color. Unpurified water was used in the wetting process, thereby introducing more minerals or impurities to the paper. As a consequence, many of these notes are very difficult to locate without discoloration, color bleeding or what looks like water staining, due to the wetting process. As if that was not enough, they were individually cut with scissors or crude cutting boards, making them very difficult to find with good margins, or the design itself not cut into it.

When grading them today, the coloration, bleeding or some stains, do not deduct from the grade, for the great majority have these problems. Margins, alignment and condition of the paper itself are the main grading points. However, when finding some of these notes without many of the usual problems, one should recognize that it is not the norm. That is one of the reasons why I have virtually all of these notes certified. They get sealed in archival holders, minimizing the aging and toning effects by not being exposed to the elements, and it also gives the client reassurance as to its authenticity and grade.

Warning:

I have seen some very white and super clean examples, but, upon close examination, they were nothing more than modern reproductions.

Powered by SixBit's eCommerce Solution